A filter press is a popular machine in industry, used for pulling solids out of liquids. The trick to how it does its job lies in a bunch of plates that are set up just right.We’re going to look at the ins and outs of how the filter press plate do their thing, what you need to know to find a filter press to buy, and tips for picking out the best maker of filter presses.

Understanding Filter Press Plates

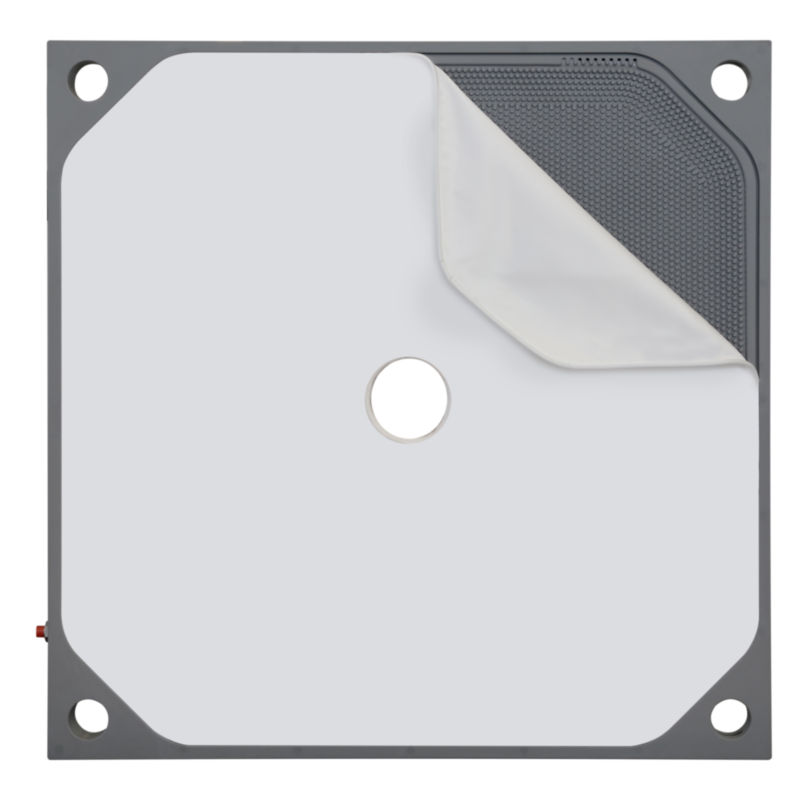

Filter press plates are the heart of the machine and play a major role in efficiency and effectiveness. Plates are typically made up of four main components: the surface, feed holes, filtrate holes, and filter cloth. Each component works together to separate solids from liquids. The surface provides a large surface area for filtration. The feed holes introduce the slurry (a mixture of liquid and solids), the filtrate holes allow the liquid to flow out, and the filter cloth fixed to the plate captures the solids.

Filter press plates are what really make a filter press work—they decide how well and how much it can filter. You can find them made out of things like polypropylene, stainless steel, or even cast iron. They come in all sorts of styles, whether that’s with little indents, stretchy membranes, or in a classic plate and frame setup. Picking the best one depends on what you’re trying to filter out, how fast you need it done, and what the plates are going to be up against in terms of chemicals.

There are several steps involved in determining the reputation and reliability of a filter press seller during the sales process:

- Assess their expertise and experience: An established seller with a history of dealing with filter presses usually implies a certain level of reliability. Check the number of years they have been in the industry and their expertise.

- Consider customer experience: You can consider online reviews and testimonials from past customers. This can provide insight into their customer service, product quality, and overall satisfaction.

- Reliability claims: Good sellers usually offer maintenance support for their products. They should be committed to providing equipment that requires minimal maintenance, is proven to be reliable, and can reduce downtime.

- Check their product range: Reputable sellers usually have a wide product range and customized solutions, indicating that they cater to different customer bases with different needs.

- Check their after-sales support: Reliable sellers usually offer comprehensive after-sales support, help with installation, provide necessary training, and provide timely repair services when needed.

Finding the Ideal Filter Press for Sale

Determining the right filter press for sale requires understanding specific application needs and operating requirements, such as capacity, dewatering efficiency, type of operation (manual or automatic), and expected size of filtered solids. The seller’s reputation and reliability also play a vital role in ensuring you receive a machine that meets industrial requirements. In addition, after-sales service, including parts availability and maintenance support, must also be considered.

When looking for a filter press for sale, consider whether a new or refurbished unit would best suit your budget and needs. New presses offer the latest technology and warranties, while older presses can be more cost-effective, as long as they are properly maintained. Evaluate key filter press parameters, such as filtration area, cycle time, and cake discharge mechanism. In addition, consider ease of operation, cleaning, and maintenance requirements to ensure long-term productivity.

Working with a Reliable Filter Press Manufacturer

Choosing the right press filter manufacturer is a critical business decision. Top-notch makers of filter presses make sure their gear is up to code and fits what their buyers need to a T. Before you decide on one, it’s smart to think about how solid their reputation is, if their equipment is of good quality, if they’re following the safety rules, and what other customers have said about them. Plus, they should have your back after you’ve bought their stuff by having all the key bits, like filter press plates, on hand and offering help to keep things running smoothly.

The press filter manufacturer not only provide high-quality products, but also invest in research and development to provide innovative solutions for evolving industry needs. Look for a manufacturer with a proven track record of providing presses that meet international quality standards. Custom solutions can greatly improve the efficiency of your filtration process. Seek out manufacturers that offer tailor-made designs, including custom plate sizes, automation options, and ancillary equipment integration. After-sales support is critical. Make sure the press filter manufacturer provides comprehensive technical support, spare parts availability, and timely service. A strong commitment to customer satisfaction is the hallmark of a trustworthy partner.

Summing up, those big squeeze machines called filter presses are super important for a bunch of jobs like cleaning up water, digging for minerals, and making food. Knowing the nitty-gritty of buying one, picking out top-notch filter plates, and going for a filter press maker that knows their stuff are all really key for nailing a smooth and spot-on separation process in your industry. When you get the right filter press, it makes things run way better and can really make a difference in how well your business does.