When it comes to industrial filtration, quality and new ideas are key, especially with filter plates and filter presses. Filter plates are used a lot in different industries, like chemical, pharma, food and drink, mining, and cleaning up wastewater. They help get rid of solids from liquids, making sure the final liquid is clean and that waste is handled well. This article will look at those who make filter plates and presses, showing the ones that are really good at making these parts.

Filter Plate Construction and Function

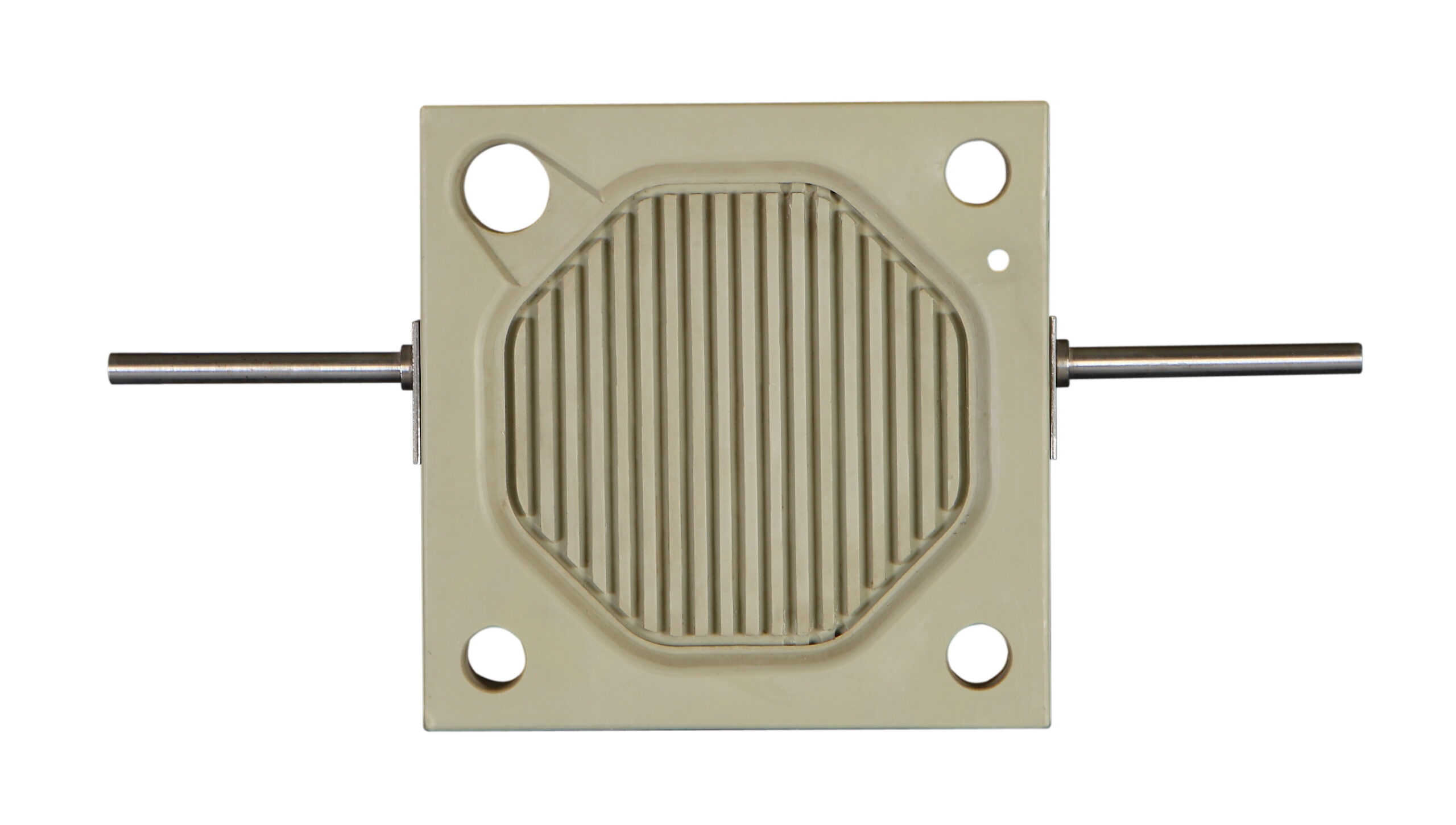

Filter plates are made from tough stuff like polypropylene, stainless steel, or other materials that don’t rust and can take a lot of pressure. They have holes in them or a special coating that lets the liquid go through but keeps the solid stuff back. When you put them all in a filter press, they make little rooms where the filtering happens.

A mix of solid and liquid, called a slurry, gets pushed into the press. When you squeeze the plates tightly, usually with a hydraulic system, the liquid gets pushed out through the small holes or the filter layer, and the solid stuff gets left behind as a cake on the plate. After the press has done its job, you take off the solid cake, and the plates are good to go for another round.

Quality is at the heart of filter plate manufacturers

Filter plate manufacturer is at the forefront of developing new mediums and designs to improve percolation performance. This section highlights advancements such as higher cake densities in membrane plates, versatile applications of alveolar designs, and environmentally friendly materials that promote sustainability. It highlights the importance of R&D in manufacturing plates that withstand harsh chemicals, high temperatures, and heavy-duty cycles while optimizing throughput and reducing operating costs.

Filter plates are an integral part of a wide range of businesses, from wastewater treatment centers to food processing plants. Filter plates are super important in filter presses, basically running the show for controlling liquids. The folks who make these plates really care about making them tough so they can stand up to the hard work in factories and plants. Nowadays, makers of filter plates use the latest technology to create ones that are strong, work really well, and last a long time. They’re always looking out for what buyers need too, making sure their plates work right for all kinds of jobs across different industries.

Where innovation meets output: the filter plate factory

A peek inside a filter plate factory reveals a blend of automation, lean manufacturing practices, and green initiatives. We explore how modern factories utilize robotic assembly lines, IoT-monitored real-time quality control, and energy-efficient systems to minimize waste and carbon footprints. Emphasis is placed on factories that adopt circular economy principles, recycle waste, and use renewable energy to responsibly produce filter plates.

A look into the world of filter plate factory provides insight into the birthplace of these vital industrial components. These factories, committed to the pursuit of precision, produce countless filter plates for a variety of operational needs. More than just manufacturing units, these factories are centers of innovation and efficiency, using advanced production methods to optimize processes and output. Utilizing state-of-the-art machinery, a skilled workforce, and innovative production techniques, filter plate factories strive to produce top-quality products while adhering to environmental and safety standards.

The World’s Most Advanced Filter Press Manufacturers

Filter press manufacturers hold the key to integrating innovative filter plates into comprehensive filtration solutions. This section highlights manufacturers that excel in custom engineering presses to suit the unique needs of a variety of industries. It emphasizes the importance of modularity, ease of maintenance, and integration of smart systems that allow for remote monitoring and control.

Filter press manufacturer is the creators of complex machines that rely heavily on high-quality filter plates. As such, they play an integral role in providing critical filtration solutions to multiple industries. Filter press manufacturers invest heavily in research and development, continually pushing the boundaries of design and functionality to create machines that effectively separate solids and liquids. These manufacturers relentlessly maintain high quality and performance standards, contributing to a cleaner, more efficient industrial world.

Filter plate manufacturers, plate factories, and filter press manufacturers together weave a rich picture of industrial excellence. Each of these entities plays a unique yet interconnected role that forms the backbone of the filtration industry, powering it and driving it forward. Although they work behind the scenes, the importance of their contributions to various industries is undeniable and vital.